In 2010, we were called upon by Y-Tec to collaborate on a technological development for monitoring processes in Oil & Gas. From that moment, we began to delve into and learn about Upstream operations, specializing in the development of robust, industrial-quality sensors for application in productive assets and field processes.

In collaboration with a significant operator, we developed the first Wireless Dynamometer, composed of a wireless load cell and an inclinometer that reported force and position data to a receiving base.

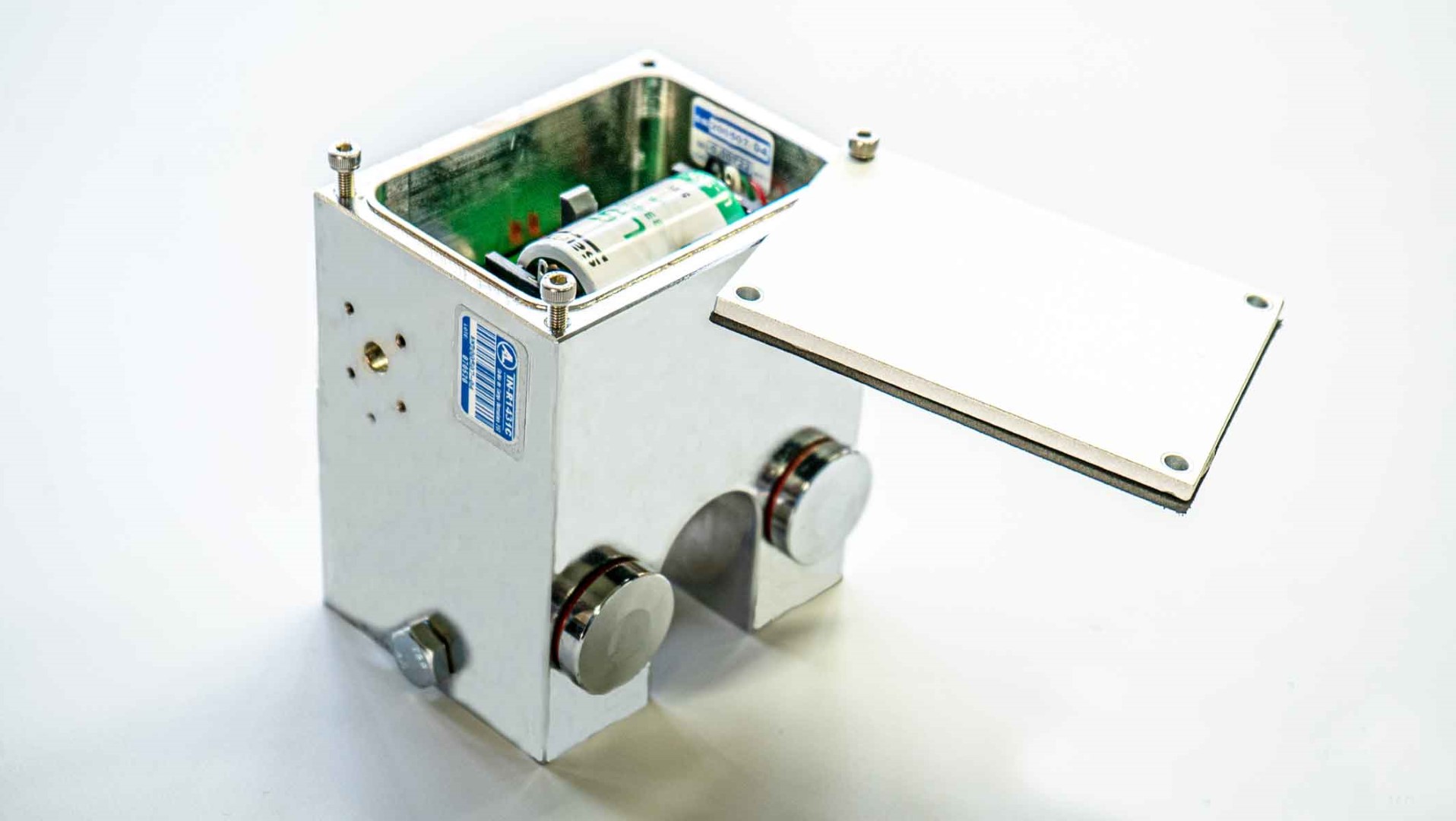

With this data, we graphed the first surface dynamometer cards. This initial milestone led us to start developing an algorithm to calculate the downhole card from the surface card and to begin with a second version of the Dynamometer. This time, replacing the inclinometer with an accelerometer built into the load cell. Additionally, we started experimenting with different types of connectivity to transmit data to the cloud.

Our History

With this new achievement, already having several devices reporting continuously, we began working on processing raw data and refining the downhole card calculation. Additionally, we started designing the user interface for visualizing dynamometer cards and other important parameters derived from dynamometries.

In this way, we took another step and successfully obtained the commercial version for the Wireless Dynamometer product.

In 2019, we initiated the mass installation of equipment, illuminating a significant portion of an oilfield with dynamometers that enable continuous monitoring of the performance of pumping units. Catering to the needs and infrastructure conditions of different operators, we offer a wide range of connectivity options: GPRS, LoRaWAN, SigFox, Ethernet, WiFi, Bluetooth, among others.

Additionally, we developed an EDGE processing PumpOff module that allows for actions on the pumping unit based on the system diagnosis.

From this point onward, we began addressing other challenges that allowed us to expand our product and service offerings for the Oil & Gas industry. We developed the Digital Level Meter, an autonomous device that provides continuous insights into downhole fluid level variations.

By emitting a large number of sub-acoustic waves in the form of pulse trains at very low frequencies and averaging the received echoes, we were able to determine fluid levels with great precision.

The inventive merit and degree of innovation of the mathematical signal processing and acquisition method for this purpose allowed us to file a patent application in both Argentina and the United States, which were granted later.

We began working on the first functional prototype for field installation, and less than 4 months later, we achieved the goal.

The equipment performed successfully, and its operation led to a series of iterations to improve the construction quality of the device and the robustness of the signal processing system. After a year of iterations, we successfully obtained version 1.0 of the Digital Level Meter, culminating in this achievement with an initial production batch and installation of the equipment in the field.

12/3/2024

The RFI Oil & Gas team successfully completed the installation of new WellSentinel dynamometer equipment in oil wells in southern Argentina. We are pleased to report that these assets are now operational and transmitting data to the new visualization software. Congratulations to the team for their dedication and achievements in this important project!